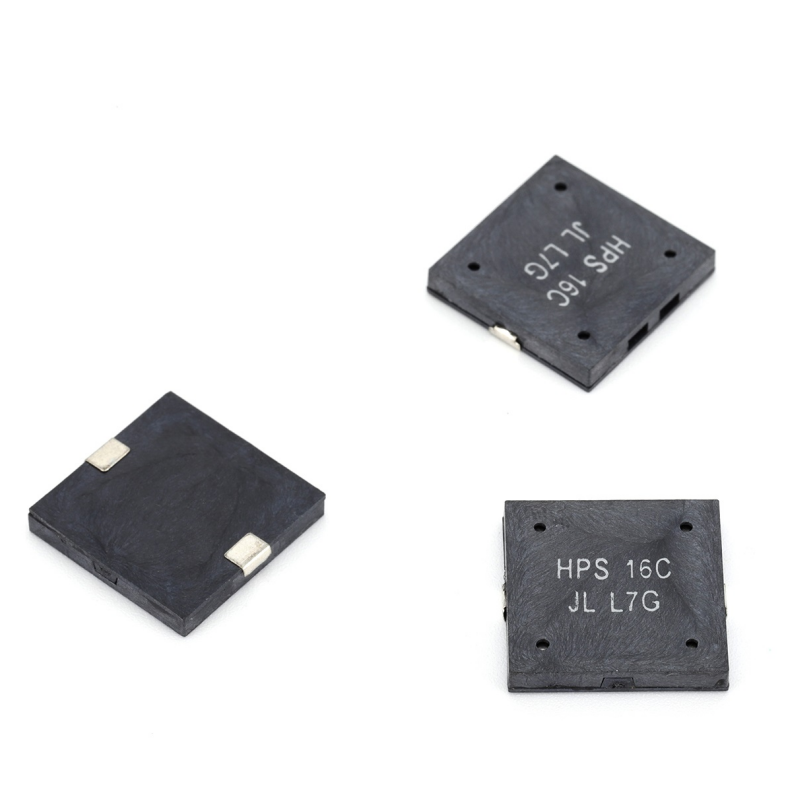

Hydz16mm 2.5 Height Square Smd Mtundu wa HYG1625A

Makhalidwe Amagetsi

| Kanthu | HYG1625A |

| Opaleshoni ya Voltage | Max25Vp-p

|

| Resonant Frequency | 4000±300HZ |

| Kugwiritsa Ntchito Panopo | Max 5mA pa 12Vp-p/Square Wave/4KHz

|

| Mlingo wa Pressure Level | Min 80dB pa 10cm/12Vp-p/Square Wave/4KHz

|

| Mphamvu ya Electrostatic | 16000±40%pF pa 1 KHz/1V

|

| Kutentha kwa Ntchito (℃) | -20 ~ +70

|

| Kutentha Kosungirako (℃) | -30 ~ +80

|

| Zida Zanyumba | LCP (Wakuda) |

| Dimension | L16.0×W16.0×H2.5mm

|

PS: Vp-p=1/2duty, square wave

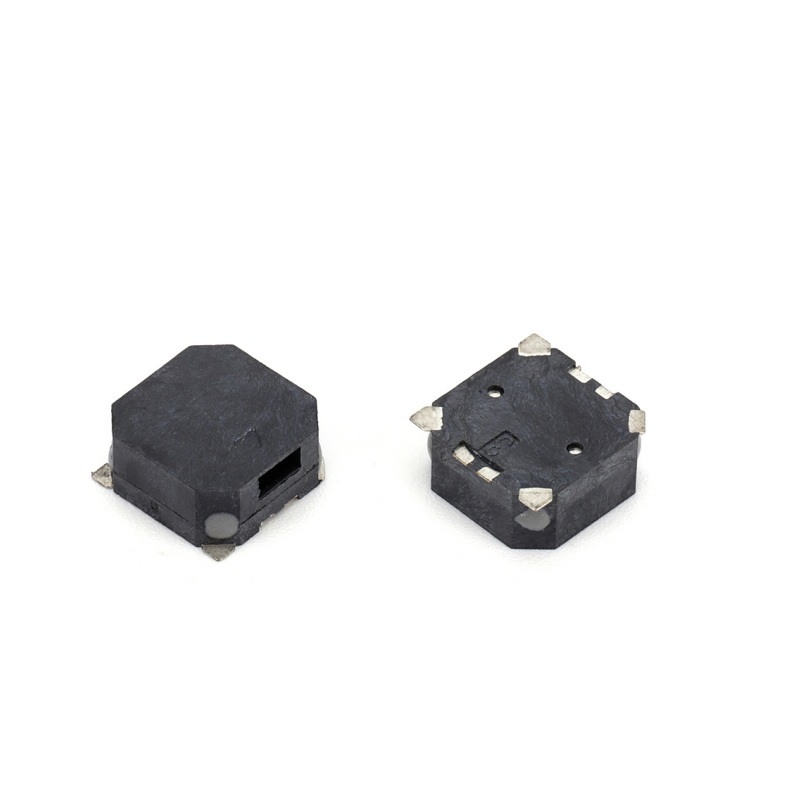

Makulidwe ndi Zinthu

Kutengera mwayi paukadaulo wokulirapo komanso makina opangira zida ndi zida za ceramic zogwira ntchito kwambiri, zowulira za SMD piezoelectric zimagwirizana ndi kapangidwe kake kakang'ono ka zida zamagetsi.

Mapulogalamu

1. Zida zosiyanasiyana zamaofesi monga makina osindikizira a PPC ndi kiyibodi

2. Zida zapakhomo monga uvuni wa microwave, zophika mpunga ndi zina.

3. Kutsimikizira phokoso la zipangizo zosiyanasiyana zomvetsera

Zindikirani (Soldering ndi Mounting)

1. Kukwera

Mukayika mtundu wa pini wazinthu pa bolodi yosindikizidwa, chonde ikani mapiniwo pabowo la bolodi.Ngati chinthucho chikanikizidwa kuti theminali isakhale mu dzenje, mapini amatha kukankhidwira mkati mwa chinthucho ndipo mawuwo akhoza kukhala osakhazikika.

2. Bolodi yokhala ndi mbali ziwiri Chonde pewani kugwiritsa ntchito bolodi yokhala ndi mbali ziwiri.Ngati solder yosungunukayo ikhudza pansi pa pini, gawo lina la pulasitiki likhoza kusungunuka ndipo phokoso likhoza kukhala losakhazikika.

3. Soldering Zinthu

(1) Mayendedwe a soldering amtundu wa pini terminal

· Kutentha: mkati mwa 260°C±5°C

Nthawi: mkati mwa 10±1 sec.

· Soldering mbali ndi kutsogolera materminal kupatula 1.5mm kuchokera mankhwala thupi.

(2) Chonde musasunge zinthuzo pansi popanda chilichonse kuti mupewe malo achinyezi komanso/kapena fumbi.

(3) Chonde musasunge malondawo m'malo monga pamalo otentha otentha kapena malo aliwonse omwe amawoneka ndi dzuwa kapena kugwedezeka kwambiri.

(4) Chonde gwiritsani ntchito mankhwalawo mwamsanga phukusilo litatsegulidwa, chifukwa zizindikirozo zikhoza kuchepetsedwa bwino, ndi / kapena zowonongeka chifukwa cha kusungirako pansi pazovuta.

(5) Chonde onetsetsani kuti mufunsana ndi woimira malonda kapena mainjiniya nthawi iliyonse yomwe zinthuzo zikuyenera kugwiritsidwa ntchito pazomwe sizinalembedwe pamwambapa.

4. Malo Ogwirira Ntchito

Izi zidapangidwa kuti zizigwiritsidwa ntchito m'malo wamba (kutentha kwachipinda, chinyezi komanso kuthamanga kwamlengalenga).

Osagwiritsa ntchito zinthu zomwe zili mumlengalenga monga chlorine gasi, asidi kapena mpweya wa sulfide.

Makhalidwe amatha kuchepetsedwa potengera momwe mankhwala amagwiritsidwira ntchito ndi zinthu zomwe zimagwiritsidwa ntchito.

(2) Kuwotchera ndi chitsulo chachitsulo chamtundu wa pini

· Kutentha: mkati mwa 350±5°C

· Nthawi: mkati mwa 3.0±0.5 sec.

· Soldering mbali ndi kutsogolera materminal kupatula 1.5mm kuchokera mankhwala thupi

(3) Reflow soldering chikhalidwe cha pamwamba mounting mtundu

Kutentha: Chithunzi 1

· Chiwerengero cha nthawi: Pakatikati pa 2

4. Kusamba

Chonde pewani kutsuka, popeza mankhwalawa siwosindikizidwa.

5. Pambuyo Kuyika Zogulitsa

(1) Ngati mankhwalawa akuyandama kuchokera pa bolodi losindikizidwa, chonde musakankhire.Mukakanikiza, pin terminal imakankhidwira mkati mwa chinthucho ndipo mawuwo amatha kukhala osakhazikika.

(2) Chonde musagwiritse ntchito mphamvu (kugwedezeka) kwa mankhwala.Ngati mphamvu ikugwiritsidwa ntchito, vutoli likhoza kutha.

(3) Ngati mlanduwo wachoka, chonde musagwirizanenso.Ngakhale zitawoneka kuti zabwereranso ku zoyamba, zomveka zimatha kukhala zosakhazikika.

(4) Chonde musawuzire mpweya pa chinthucho mwachindunji.

Mpweya wowombedwa umagwiritsa ntchito mphamvu ku diaphragm ya piezoelectric kudzera pabowo lotulutsa mawu;ming'alu imatha kuchitika ndiyeno mawuwo amakhala osakhazikika.Kuphatikiza apo, pali kuthekera kuti mlanduwo ukhoza kutha.

Chidziwitso (Kugwira)

1. Piezoelectric ceramic imagwiritsidwa ntchito pamtunduwu.Chonde gwiritsani ntchito mosamala, chifukwa ceramic imasweka pakagwiritsidwa ntchito mwamphamvu.

2. Chonde musagwiritse ntchito mphamvu pa diaphragm ya piezoelectric kuchokera ku dzenje lotulutsa mawu.Ngati mugwiritsa ntchito mphamvu, ming'alu imachitika ndipo mawuwo amatha kukhala osakhazikika.

3. Chonde musagwetse mankhwalawa kapena kugwiritsa ntchito kugwedeza kapena kusintha kwa kutentha kwa izo.Ngati ndi choncho, LSI ikhoza kuwonongedwa ndi mtengo (surge voltage) wopangidwa.ikuwonetsa chitsanzo choyendetsa dera pogwiritsa ntchito zener diode.

Chidziwitso (Kuyendetsa)

1. Kusuntha kwa Ag kumatha kuchitika ngati magetsi a DC ayikidwa pa chinthucho pansi pa chinyezi chambiri.Chonde pewani kuzigwiritsa ntchito pansi pa chinyezi chambiri ndikupanga dera kuti lisagwiritse ntchito magetsi a DC.

2. Mukamayendetsa malonda ndi IC, chonde ikani kukana kwa 1 mpaka 2kΩ mndandanda.Cholinga chake ndi kuteteza IC ndi kupeza mawu okhazikika.(Chonde onani mkuyu 2a).

Kuyika diode mofanana ndi mankhwala kumakhala ndi zotsatira zofanana.(Chonde onani mkuyu 3b)

3. Flux kapena Coating Agent, etc., Zosungunulira Zosiyanasiyana

N'zotheka kuti zosungunulira zamadzimadzi zilowe mkati mwa mankhwalawa, popeza mankhwalawa siwosindikizidwa.Ngati madzi alowa mkati ndikumangidwira ku diaphragm ya piezoelectric, kugwedezeka kwake kumatha kuletsedwa.Ngati mungalumikizane ndi mphambano yamagetsi, kulumikiza kwamagetsi kungalephereke.

Kuti mupewe kusakhazikika kwa mawu, chonde musalole kuti madzi alowe mkati mwa mankhwalawo.